Archive

Feb20

Top 3 Reasons not to use Brake Line Compression Fittings

Comments Off on Top 3 Reasons not to use Brake Line Compression Fittings

Normally I would start out with an interesting story. Today I will just cut to the chase. Do not use a compression fitting on your brake system. When you are on the road not only your safety but the safety of others is at risk if you have a compromised brake system. When you press your brake pedal the PSI (pounds per square inch) exerted on your brake system is great often over 1,000 PSI in normal braking.

The brakes on a vehicle deliver a critical safety feature and every driver is obligated to ensure the brake system operates properly. Even though only 5 percent of accidents in the United States are attributed to brake failure, the possibility exists, especially when someone performs faulty repairs. Brake line compression fittings are a controversial repair component and can lead to failure in the brake system.

How Does the Brake System Work?

To understand why brake line compression fittings are a poor choice for repair, understanding how the braking system works is paramount. The brake system is responsible for stopping a vehicle by apply pressure to the wheels. The most common assembly in vehicles today includes five main components: brake pedal, push rod, master cylinder assembly, brake caliper and hydraulic lines. In addition, the braking system includes brake fluid.

The brake pedal, also called a lever, is contained inside the vehicle and is used by the driver to begin the braking process. The pushrod, or actuating rod, engages with the pistons in the master cylinder assembly. The brake fluid is designed to experience little or no compression which translates into a rise in pressure throughout the entire system. This pressure equalizes through the hydraulic lines causing the pistons to place pressure on the brake pads. The rotor–a component connected to the wheels–begins to receive increasing pressure from the brake pads and lessens the speed with which the wheels turn.

It is important to know that the braking system is considered “closed,” which means that fluid does not escape the system or evaporate over time.

The Top Three Reasons to Avoid Brake Line Compression Fittings

- Compression fittings can leak at high temperatures

- Compression fittings do not provide a solid structural connection

- Compression fittings are against the law in many states

Repairing Brake Lines

Over time, your brake lines will wear down. Hard lines–made of metal–rust and rubber lines might crack or show other symptoms of stress. Once this occurs, you are faced with the decision to repair or replace the lines.

Repairing the hard lines is not recommended as the entire line needs to be replaced. This process can be difficult but it’s necessary for the safety of your vehicle. You can make it an easier job by using an easy to work with material such as our copper nickel brake tube or you can make it cheaper by buying regular steel or bundy tube line.

Brake Line Compression Fittings

Replacing your brake lines can cost several hundred dollars, at minimum, which can create a strain on your budget. Consequently, many people choose to use temporary replacement techniques to manage car repair hurdles. For example, some people choose to use a rear view mirror kit to attach a separated rear view mirror. While the rear view mirror is an important component of driving, it doesn’t influence how fast a car move, or its stopping ability, which makes it an ideal candidate for patch or repair jobs. Your brake system makes a significant difference in how safely you travel and using patch jobs to repair the system could lead to disaster.

Despite this, many people choose to try brake line compression fittings for line repairs. Compression fittings are used to join two pieces of brake line together. This form of repair is common because of the idea that the fitting prevents leakage. The compression fitting is comprised of a nut and a ferrule. When placed on a brake line, the fitting creates a tightened joint.

Unfortunately, using brake line compression fittings presents multiple problems. Because your brake system creates a substantial amount of pressure, the compression fittings are prone to failure. In addition, compression fittings are known to leak when used on brake lines, causing a loss in brake fluid, and ultimately failure of the braking system.

You cannot, under any circumstances, use compression fittings to repair the lines on a public transportation vehicle. Many states have banned the use of this repair on passenger vehicles, too. In addition, you might find that compression fittings will cause your vehicle to fail inspection.

You can, however, use this form of repair for vehicles that do not travel on public roads and highways or at a high rate of speed. For example, a ride-on lawn mower or all-terrain vehicle used for off-roading can accept brake line compression fittings.

You can also use compression fittings for temporary repairs. Temporary repairs might include those that are performed on a vehicle undergoing restoration. For example, if you need to check a vehicle’s ability to accelerate, compression fittings would work well for a closed environment.

The Best Approach to Resolve Brake Line Failures

While several components on your vehicle might benefit from temporary or patch repairs, your brakes aren’t one of them. Most professionals recommend that you simply replace the brake lines if you run into trouble. At minimum, you will need the brake lines, brake fluid and open-ended wrenches to complete the replacement. If you plan to complete the repairs, consider inspecting the entire system to determine if you should replace other components, such as calipers, pads or rotors. In addition, consider replacing the unaffected line, just in case it has undergone similar wear and tear. Handling everything at once will ensure that you do not run into problems immediately after your replacement.

Safety and law are important components of being a responsible driver. One of the most important reasons to avoid brake line compression fittings is their tendency to crack under extreme pressure, which will inevitably lead to brake system failure. Second, the law in your state might prohibit the use of these fittings for brake line repair. Consequently, passing vehicle inspections will present a challenge. Finally, replacing your brake lines will provide the best return on investment, even if it costs more than performing a repair.

Brake line compression fittings work well under certain circumstances. If the vehicle is for off-road usage or undergoing a restoration, you can use the fittings for temporary repairs. Using the fittings for public transportation vehicles or those that use public highways and roads is against the law in many states and a bad idea. Keep in mind that while the fittings offer an inexpensive alternative, they are not a long-term solution, and an accident will cost much more, financially and morally, in the long run.

Feb16

Will starting my car in cold weather and not running it long cause my car to blow a head gasket?

Comments Off on Will starting my car in cold weather and not running it long cause my car to blow a head gasket?

0.45 miles.

That’s how far my wife’s car made it before it rolled to a stop mid intersection and died.

When we were dating my wife (girlfriend at the time) had to do these clinical studies to finish her degree. Unfortunately the program coordinator wasn’t very good with geography and had her driving over an hour to “work” every day. I say she wasn’t good with geography because there were other people in the course who drove past her in the morning to do their clinicals in our town.

She called me one day and said her car was making a “noise”

When someone tells you they heard a noise it’s not good news. In fact it was the worst news. The worst part was that she started hearing the noise about halfway in her morning commute. One thing about my wife is she has always been super dedicated to not letting people down. We get 10 inches of snow and she still goes to work.

What kind of noise? I asked

Ticking? I don’t know. It’s loud.

How long did it do it?

Well it started on the way to work this morning but I just drove it anyway because I didn’t want to be late.

Oh boy.

If you’ve ever heard an engine die of no oil you know its kind of like that sound you hear early in the morning when you first start the engine. A rapid ticking ticking sound except it never goes away. In fact it usually gets louder.

I asked my dad what to do and he said it was probably too late. Just put some oil in it and try to limp it home. As I followed her home that afternoon I got to watch her roll to a stop in the middle of an intersection as the engine finally gave up.

It’s one of the worst feelings you can get. The death of a car. It’s even worse when it’s your daily driver. In the years since we’ve both gotten older and she would never make the same mistake again. Actually today we maintain the cars much better than back then so the whole thing probably wouldn’t happen anyway.

But I’m still paranoid. You probably know the feeling. It’s your only way to work. Most of us can’t afford to carry a spare car just in case a repair takes more than a day.

So I can understand when someone asks about blowing a head gasket in a weird way by driving short distances every day. I remember hearing this when I was a teenager and it’s not bad advice in general but what about those of us who have to do it. Should we drive around the block to get to 195 degrees each day even if we only need to go a mile or two down the road?

So what does happen if I don’t let my car warm up

Well unfortunately this isn’t really a solid science but there are some concrete facts you can use to make your own judgement.

Condensation can build up. You’ve seen it before. The guy in front of you at the red light has water dripping out of his tailpipe. If you go too long without getting your whole exhaust system up to operating temperature you can get water pools in odd places like the muffler. This can be really bad when it starts to rust from the inside out. Unless you think it makes you sound like you’ve got straight pipes or something. Spoiler alert: it doesn’t.

Another consideration is that oil’s consistency changes with temperature. When it’s cold it doesn’t flow as well as when it’s warm or hot. Since the oil flows out of your engine overnight it makes it harder for the engine to cycle thick cold oil into all the right places.

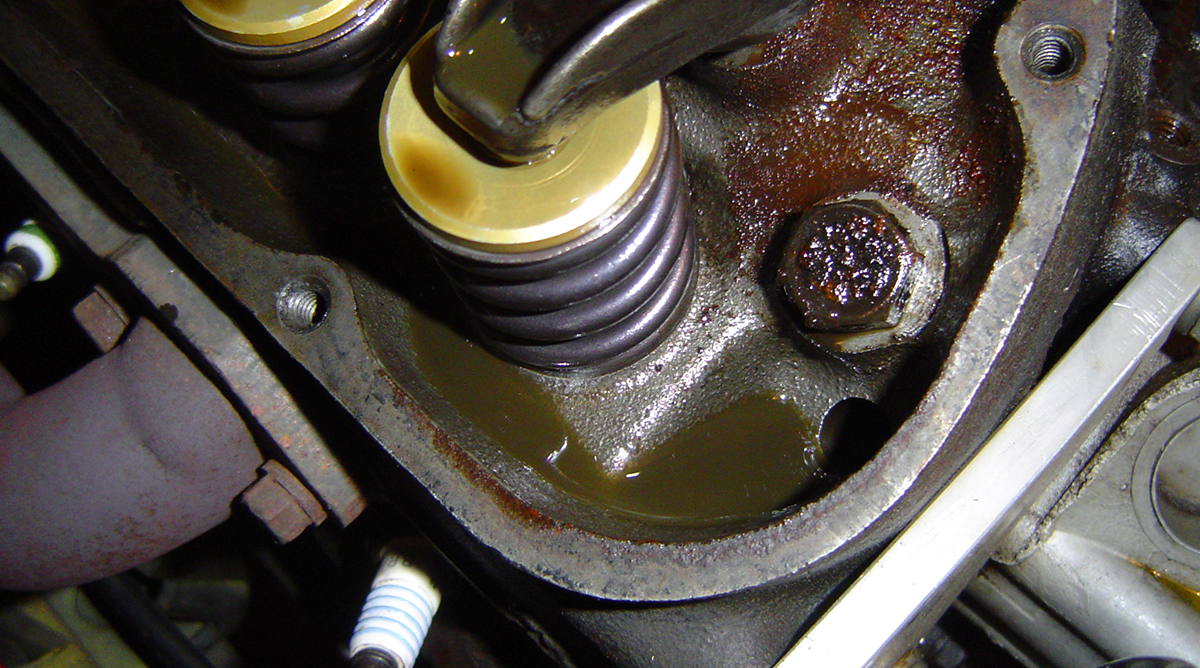

But condensation can also creep up in your oil. With the engine never getting up to normal operating temperature the small bit of water that naturally finds its way into the crankcase never gets evaporated and builds up. This leads to sludge and reduces your oils ability to lubricate. If you have ever changed your oil and had it be milky or yellowish you have a condensation problem. Or of course it could mean someone put washer fluid in the oil fill but you’ve got other problems there.

Image cropped: © Ryan Frost

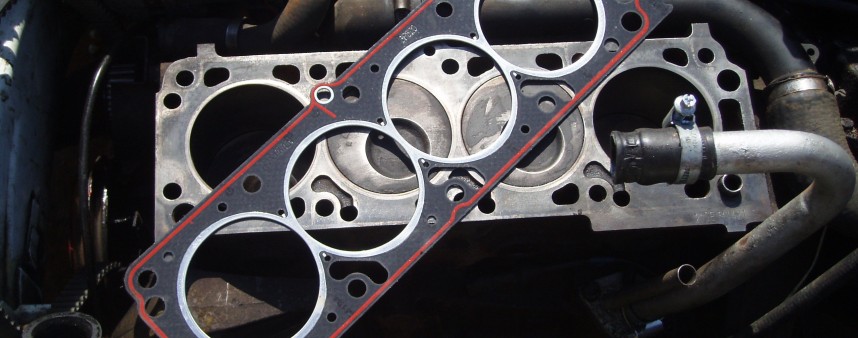

But what about my head gasket?

Well it’s probably going to be ok. Condensation can be an issue in many parts of your engine and it can cause corrosion of your head gasket. But in general you probably aren’t going to have a lot of issues caused by short term driving as long as every now and again you do get it up to operating temperature.

One thing to be careful of is don’t rev your engine up while it’s still warming. If you are just doing short 5 minute trips to work every day and someone wants to race you at the red light just say no. Engine parts ride on a thin layer of oil to keep them lubricated. This oil doesn’t stay in place when the engine isn’t running so part of the warming process is for the engine to re lubricate itself.

If you aren’t going to be driving very far it is still a good idea to let the car warm up though. If you can. And at least once a week let it get up to normal temp. This gives the entire system a chance to boil/evaporate off any water that has found its way in.

Keep Your Oil Changed and Use the Right Weight

Your owners manual specifies an oil weight and viscosity for a reason. Most modern vehicles can go more than the age old 3,000 miles to at least 5,000. Consult your manual and get your oil changed when it’s time. This alone can combat condensation build up even if you don’t do anything else. Don’t mix in extra weight oil in the hopes that it will do a better job. It won’t.

Final thoughts and tips.

It isn’t always possible but remember the following and try to do them whenever time permits.

- Don’t start the car and start driving immediately. Let it warm up as long as you can stand but at least let the RPMs drop to normal operating range before shifting gears.

- Take it easy on the transmission until the engine temp reaches operating range.

- Change your oil regularly at the indicated mileage point in your manual.

- Don’t let your oil ever run low. If you have a problem with topping off you need to check your oil ever other fill up and keep it in the operating range. When you can get the leak fixed.

If you have ever worked on the brake system of an old car chances are you’ve seen Hexavalent Chromium or Cr(VI). Introduced as a cheap alternative to zinc it provided a nice protective barrier for exposed connections. You can tell them because they are gold in color. Even today if you visit your local auto parts store you’ll find a lot of older stock that uses hexavalent chromium.

A Block Buster Movie

The dirty secret is that the process of plating items with Cr(VI) is known to cause cancer and is horrible for the environment. You may remember Erin Brockovich the true story of a legal clerk fighting for the environment (it won academy award for best actress).

We are Done With Hexavalent Chromium

Our main supplier switched plating to the better Trivalent Chromium (not perfect but significantly better for the environment and easier to avoid contamination) years ago but we still receive a handful of parts from them with the old Hexavalent plating.

So we’ve decided to drop several products with the old platting. We are sorry for any inconvenience this may cause our customers but we believe that in 2014 it’s important to make changes for the future.

Discontinued Products

Currently the following products are discontinued:

- BQ85 – M20 x 1.5 Bulkhead Nut

- BQ86 – M18 x 1.5 Bulkhead Nut

- BQ87 – M16 x 1.5 Bulkhead Nut

- BQ88 – M14 x 1.5 Bulkhead Nut

- BQ113 – 5/8 x 18NF Female Tube Joiner

- BQ128 – M10 x 1.25 No3 JIC Adapter

- BQ130 – M10 x 1.5 No3 JIC Adapter

- BQ152 – M10 x 10mm Double Banjo Adapter

Fuel Line Kit

The biggest impacted product is our fuel line repair and replacement kit. We have discussed with our supplier and unfortunately this product is sourced from various places and our request to eliminate any Hexavalent plated parts cannot be fulfilled. Unfortunately this means that we must discontinue this kit in it’s entirety. If you have purchased a fuel line repair kit and need replenishment contact us and we can put you in touch directly with someone who can help you.

You loved MacGyver, right? Of course you did. Every dude in America watched that show weekly, waiting for the moment we’d find ourselves trapped in a basement by some baddies only to escape by turning some sticks and rocks into a torpedo with the help of the boiler pipe, giving us an amazing escape. We all wanted to repair a busted fuse with a gum wrapper and give the gum to the amazed girl, securing our romantic interests while also being the hero. This was the eighties and anything was possible.

READ MORE

Nov21

4 Reasons to use Cunifer Copper Nickel Brake Line

Comments Off on 4 Reasons to use Cunifer Copper Nickel Brake Line

Cunifer or Copper Nickel line is a “new” way to make brake lines that has actually been around for many years. In fact its first commercial use dates back to the 70’s!

In this post I’m going to convince you why cunifer copper nickel line is the right choice for ANY vehicle and definitely the easiest replacement available for the shop or shade tree mechanic.

CUNIFER

The new ‘old’ material for brake lines

Last month I mentioned a `new’ product that has been around for years – only nobody knew about it. It is a material known as Cunifer – an alloy of copper and nickel with a bit of iron and manganese thrown in for good measure.

The banjo bolt is what connects your brake hose fitting to the caliper providing a necessary connection to get the fluid to the brakes where it’s needed. Our brake hose banjo bolts are made from high quality steel and plated for maximum corrosion resistance. Unlike any other site we stock a complete line of standard and metric thread bolts including hard to find configurations.